There is no doubt that the manufacturing sector is undergoing a massive transformation. The days of large, centralized factories are giving way to a new era of smaller, more agile plants. Manufacturers are increasingly turning to analytics to help them optimize their operations. By harnessing the power of data, manufacturers can optimize their operations, improve quality, throughput, and efficiency, and reduce costs. Keep reading to learn more about the future of manufacturing analytics.

Manufacturing analytics is the collecting, analyzing, and interpreting data to improve manufacturing processes. This data can come from various sources, including sensors on machines, production logs, quality control data, and customer feedback. By analyzing this data, manufacturers can identify problems and opportunities for improvement. For example, by tracking sensor data, manufacturers can identify when a machine is about to break down and schedule repairs before it becomes a problem. Manufacturing analytics can also help manufacturers optimize their production processes to reduce waste and save money. In addition, by analyzing customer feedback, manufacturers can determine which products are most popular and change their product lines accordingly.

In the coming years, we can expect to see even more sophisticated analytics tools and techniques used in the manufacturing sector. These tools will help manufacturers optimize their operations and predict and prevent problems before they occur. We can also expect to see a growing emphasis on using data-driven insights to improve product design and development. By using analytics to better understand how products are used in the real world, manufacturers can create more efficient, profitable, and customer-friendly products. Finally, we can expect to see continued growth in using predictive analytics in the manufacturing sector. Predictive analytics can help manufacturers identify potential problems and trends before they become serious issues. By using predictive analytics, manufacturers can take proactive steps to address these issues and improve their overall performance.

Nanotechnology is Changing Production

Nanotechnology is a process of working with materials at the atomic and molecular levels to create new products. Nanotechnology is changing how we produce products because it allows us to develop products with specific properties that cannot be achieved with traditional manufacturing processes. Nanotechnology can be used to create coatings that make products more resistant to scratches and corrosion. It’s also used to develop materials that are stronger, lighter, and more durable than traditional materials. As a result, nanotechnology is making it possible to manufacture products that are more efficient and durable than ever before.

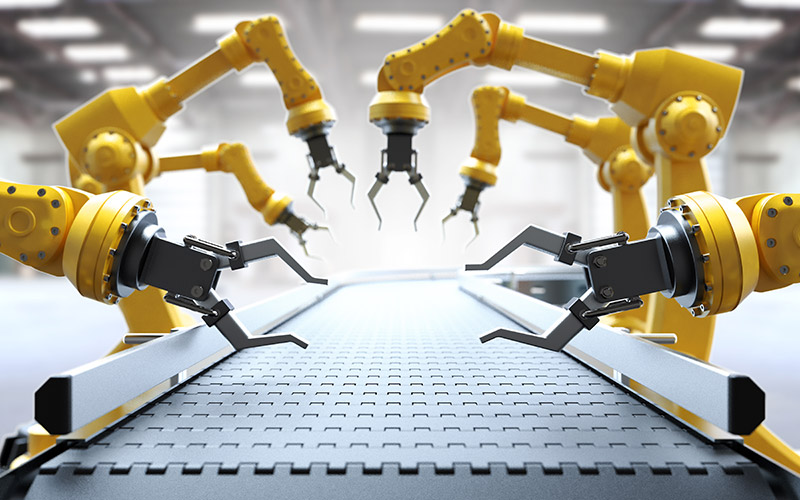

Reliance on Smart Factories

The future of manufacturing is reliant on smart factories. These factories are equipped with real-time sensors and data analytics tools that can track production. This enables manufacturers to identify and correct problems, improving quality and efficiency. Additionally, intelligent factories can use machine learning algorithms to predict equipment failures and schedule repairs accordingly. They are more efficient, reliable, and responsive than traditional factories.

Edge Computing is Changing How Data is Processed and Analyzed

Edge computing is an architecture that moves some or all computing and storage functions away from centralized data centers to places where the data is created or used. Edge computing is a newer technology used to process and analyze data. It’s different from traditional computing because it does not rely on a centralized system.

Edge computing brings computing and storage closer to the user or the things being controlled or monitored. It can improve performance and responsiveness for industrial control systems and other applications by reducing the distance the data travels. Edge computing can also improve security by reducing the number of potential attack surfaces and enabling data to be processed and acted on closer to where it is generated.

3D Printing is Disrupting Traditional Manufacturing Processes

3D printing technology is quickly disrupting traditional manufacturing processes. These printers can create three-dimensional objects by layering materials. This technology is becoming more affordable and accessible and can revolutionize how products are designed and produced, making it possible to create customized items on demand. 3D printing could also significantly impact the environment, as it would eliminate the need for many traditional manufacturing processes involving shipping products across the globe.

The Future of Supply Chains Rests on Blockchain

Blockchain technology is making its way into various industries, and supply chain manufacturing is one of them. The future of manufacturing rests on the blockchain. The blockchain is a distributed database that allows for secure, transparent, and tamper-proof transactions. This makes it an ideal technology for supply chains and other domains of change management.

Blockchain technology can potentially improve manufacturing by optimizing the manufacturing process and reducing the risk of product recalls. Blockchain can help streamline the supply chain by automating the flow of information between suppliers, manufacturers, and customers. This can help reduce the time it takes to get a product from the factory to the shelves.