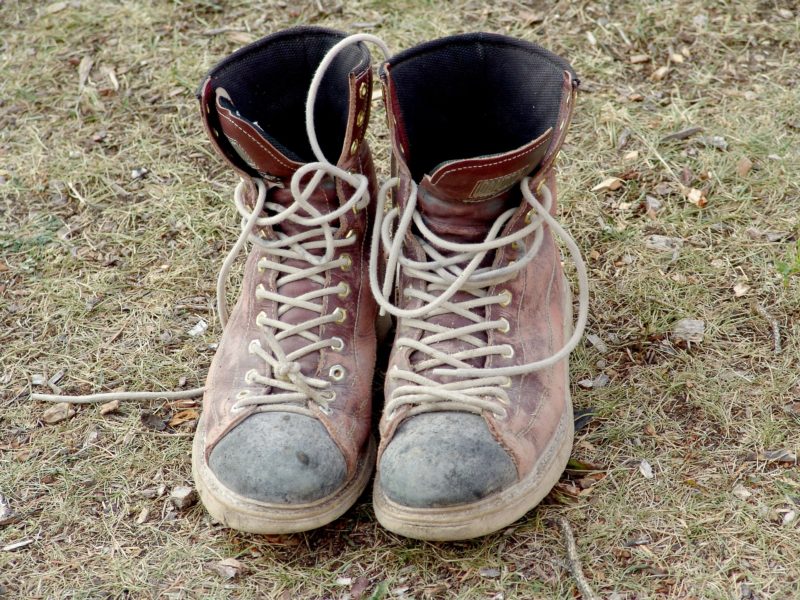

People that are regular buyers of PPE know about the quality of steel-toe boots. They know all about the benefits and protection that steel gives. But, here and there, even the biggest skeptics hear about composite-toe boots.

There’s a reason why they refuse to wear them – It’s not as simple as it seems.

The Dilemma

To learn more about the product, you can find composite toe boots here. To put it simply, composite-toe boots are like other PPE boots, except they use composite materials for protection.

Steel remains in use for over 100 years. The reason for this is the performance that lasts for a century. It’s hard to compress or puncture steel, especially when you can meld it as an alloy. However, even steel has its disadvantages.

The steel-toe box is under the influence of weather and other conditions. For example, in winter steel becomes heavier and it could damage your feet. Or, in summer and warm environments it could get so hot that it burns your feet.

There’s even a chance that steel could be an electric conductor. Finally, steel becomes a hindrance when your boot gets in contact with flammable chemicals.

But, let’s get it straight. Steel works.

However, some things can work better than steel.

Composite vs Steel

Composite materials allow you to get more out of work boots. Composite-toe boots are crafted from a material mash to attain certain properties. For example, you can get a lightweight but durable toe-box. It allows easy movement in the winter and protects your feet.

Does that mean that composite-toe boots are superior? Not exactly.

Composite-toe boots are good for a specific purpose. Steel-toe boots win when it comes to general conditions and general use. You can purchase steel-toe boots knowing you’ll get optimal protection in various terrains, conditions, and climate.

However, composite-toe boots could prove superior in controlled conditions. But, if you switch the worksite, and there’s a big temperature change – They can deteriorate fast and lose their advantage.

Still, composite-toe boots remain one of the best PPE solutions on the market.

Developer Trends

Developers of PPE want a single thing – A work boot that does more and performs better. Steel, while it has many qualities, has a finite set of qualities. You can’t improve steel beyond what it already offers. If the needs of industry change – You can’t change steel.

Maybe you can create an alloy. However, melding an alloy can get problematic or expensive to meld. From a developer’s point of view, it means that the production is too expensive.

Or, there may be new industry developers who want to enter first with their PPE. If it happens so that you can’t use steel efficiently, you’ll have to switch to compound materials.

PPE isn’t an industry in which nothing changes. Instead, developers have to improve and tweak constantly. They have to look past that.

Future Design

First, you have to look at the future of design. Compare the work boots today and those from 50 years ago. They are leaner, smaller, and they look like regular boots. The work boots lost bulkiness to accommodate the workers as they had to use more ergonomic machines.

This trend remains in all aspects of industry and tech. To make the work boot even lighter, you’ll have to reduce the use of steel for protection. Instead, developers will use composite materials for protection.

Among all advantages, composite materials can last longer than steel. You can develop them this way.

Last Longer

Composite-toe boots can last longer. Steel-toe boots have a major flaw. Once you expose the steel-toe plate, you can throw away the boots. It’s not possible to mend the boot once the steel protrudes out.

However, composite-toe boots often employ material mashes and custom materials for the whole boot. You can use leather, nylon, plexiglass, or another material mash and meld with a composite plate.

When parts have similar materials you can mend them together. To reduce tears, developers use similar materials. And, when you have a durable work boot with a strong plate, it’s going to last longer.

Do More

Also, it does more. Once you have a strong toe-plate, you can add other characteristics. For example, the main weakness of steel is that it’s a great electrical conductor. If there’s a mishap with electricity, and a cable hits your feet, you can suffer electrical damage.

Instead, you can use composite materials to reduce such weakness and get more protection. The whole point of composite materials is to subtract the qualities you need and craft a better material.

Now, that you have better material, you can increase efficiency.

Better Performance

The first thing you want to improve is performance. Every brand is looking for a work boot that lasts longer, is durable, and can perform in various environments and climates. The holy grail of every PPE boot developer is to find a general-purpose work boot.

Whether they like it or not, developers have to choose composite-toe over steel-toe if they want to progress. Steel, while amazing, has limitations. Composite materials’ only limit is that of experimentation and imagination.

Finally, when you have a composite-toe boot you can couple it with other composite materials. That means you can make it impossible to wear down.

Durable

Composite-toe boots can last longer than regular steel-toe boots. The reason for that is that you can meld the entire boot to be resistant to wear and tear. And, when you are crafting the boot for a specific workplace, you can battle the hazards of the workplace.

The superiority of the composite-toe boots is that you can use material mashes to get the most of the protection. You can’t use them for general purposes as effectively as steel-toe boots. However, when you look at specific worksites, the composite-toe boot remains peerless.

You should improve your equipment.

Buy Composite Toe Boots

Composite-toe boots are the future of the PPE industry. The needs of the industry are going to become even more specific.

Go with the trends. Get the most of the protection you can get with composite toe boots.